High-Performance Tapes

Discover our range of high-performance tapes for specialized environments.

Video of us Testing ACXplus out on a Luton Van

Pull Test Rivets

Localized Stress Points: Rivets concentrate force at individual points, potentially leading to material fatigue or failure under high loads. Inconsistent Load Distribution: Unlike adhesives, rivets don’t evenly distribute stress across the entire joint area. Vulnerability to Vibration: Constant vibration in vehicles can cause rivets to loosen over time, compromising joint integrity.

Corrosion Susceptibility: Rivet holes can become entry points for moisture, leading to corrosion and weakening the overall structure. Material Limitations: Rivets may not provide optimal strength for joining certain material combinations, especially dissimilar metals or composites. Potential for Cracking: The installation process of rivets can create micro-cracks in surrounding material, potentially weakening the joint.

Limited Flexibility: Rigid rivet connections may not accommodate thermal expansion or contraction as well as flexible adhesive bonds. Fatigue Vulnerability: Repeated stress cycles can cause fatigue failure around rivet points more easily than with distributed adhesive bonds.

Vibration Vulnerability

Vibration-induced loosening can lead to rattling, reduced performance, and even catastrophic failure if critical components become detached.

Fasteners can loosen over time due to constant vibrations, compromising structural integrity.

This is particularly problematic in applications subject to continuous movement or oscillation, such as vehicles or machinery.

In high-vibration environments, fasteners may require frequent retightening or the use of specialized locking mechanisms, increasing maintenance costs and complexity.

Vibration-induced loosening can lead to rattling, reduced performance, and even catastrophic failure if critical components become detached. more..

Stress Concentration

To mitigate this issue, engineers often need to overdesign parts or use additional reinforcement, adding weight and complexity to the assembly.

Fasteners create stress points in materials, which can lead to fatigue and eventual failure.

These concentrated stress areas are often the initiation points for cracks or fractures in the material.

The stress concentration effect is particularly pronounced in thin materials or those subject to cyclic loading.

To mitigate this issue, engineers often need to overdesign parts or use additional reinforcement, adding weight and complexity to the assembly.

Weight Penalties

The use of lightweight fasteners (e.g., titanium) can mitigate this issue but significantly increases costs.

The cumulative weight of numerous fasteners can be significant, particularly in industries like aerospace where weight is critical.

This added weight can impact fuel efficiency, payload capacity, and overall performance of the final product.

In transportation applications, every gram of weight translates to increased fuel consumption over the life of the vehicle. more..

Temperature Sensitivity

In aerospace or automotive applications, where temperatures can vary dramatically, this sensitivity can lead to reduced reliability and increased maintenance requirements.

Extreme temperature fluctuations can cause materials to expand and contract, potentially leading to fastener failure.

This thermal cycling can create gaps, loosen connections, or even cause fasteners to shear under extreme conditions.

Different thermal expansion rates between fasteners and joined materials can lead to stress buildup, potentially warping or damaging the assembly. more…

Corrosion Susceptibility

Corrosion protection methods like plating or coatings add cost and can be damaged during installation, reducing their effectiveness.

Metal fasteners are prone to corrosion, especially in harsh environments or when different metals are in contact.

Corrosion can weaken the fastener, leading to premature failure and potentially contaminating the surrounding materials.

Galvanic corrosion, occurring between dissimilar metals, can be particularly aggressive and difficult to predict or prevent.

Corrosion protection methods like plating or coatings add cost and can be damaged during installation, reducing their effectiveness. more..

Maintenance Requirements

In hard-to-reach areas, maintenance of fasteners can be particularly challenging and time-consuming.

Fasteners often need regular inspection and re-tightening, adding to long-term maintenance costs.

This ongoing maintenance increases the total cost of ownership and can lead to downtime in critical systems.

Fastener replacement during maintenance can damage threads or holes, potentially requiring more extensive repairs. more…

Material Limitations

Some materials, like certain plastics or ceramics, may be too brittle or soft to be reliably fastened using traditional methods.

Traditional fasteners may not be suitable for joining certain materials, especially dissimilar ones.

This limitation can restrict design options and force compromises in material selection for optimal performance.

Fastening methods for composite materials often require special considerations to avoid delamination or fiber damage.

Aesthetic Drawbacks

The need to accommodate fastener heads in the design can limit the sleekness and modernity of product aesthetics.

Visible fasteners can detract from the appearance of the final product, necessitating additional finishing work.

In consumer products or architectural applications, visible fasteners may be seen as outdated or less premium.

Hiding fasteners often requires additional design elements like caps or covers, adding to part count and assembly complexity.

The need to accommodate fastener heads in the design can limit the sleekness and modernity of product aesthetics. more...

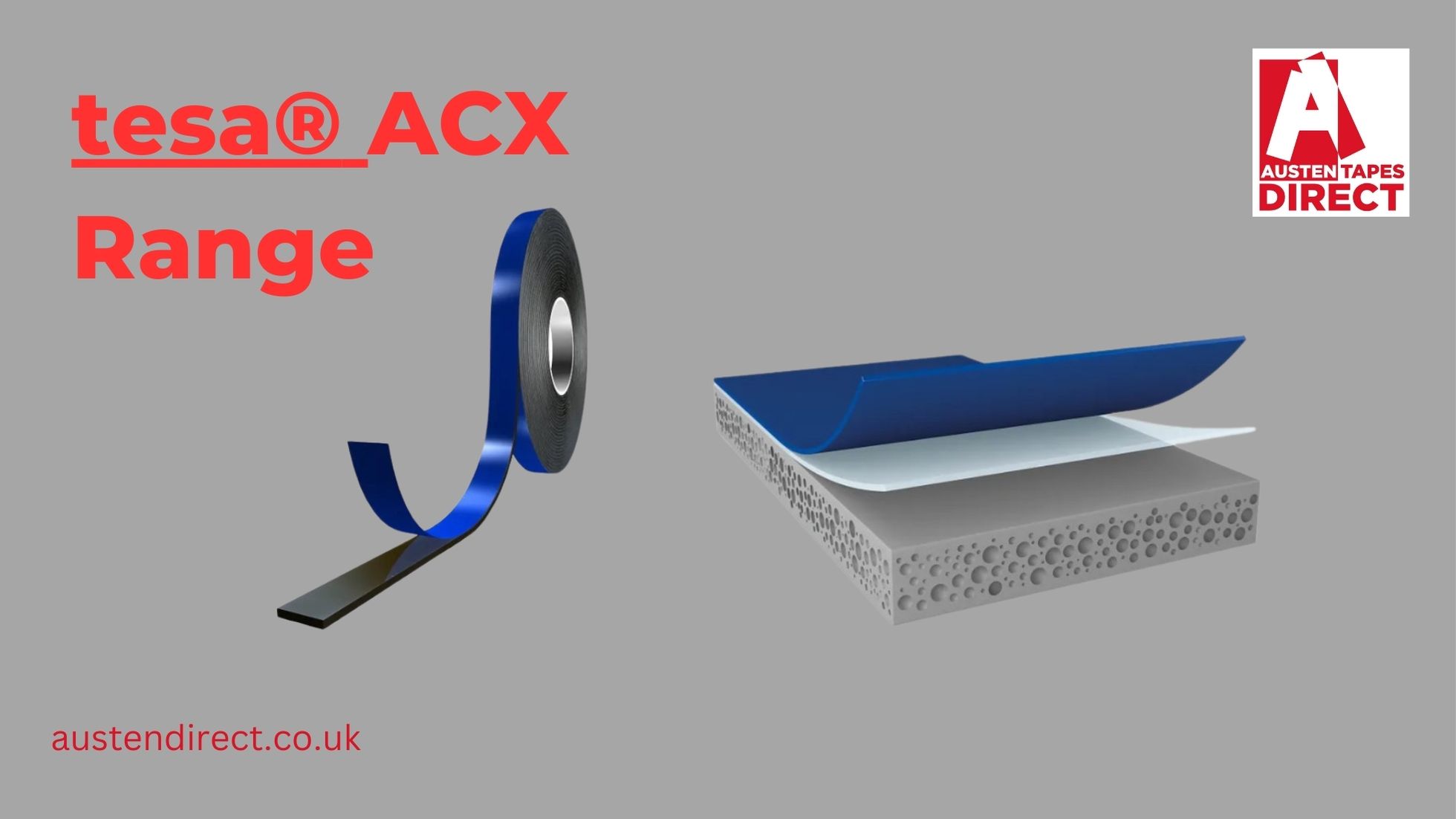

Pull Test ACXplus

Superior Pull Strength: As demonstrated in the pull test, tesa® ACXplus 7811 outperforms traditional rivets in resisting pulling forces. Uniform Load Distribution: Adhesive spreads force across the entire bonded area, reducing stress concentrations. Vibration Resistance: The viscoelastic properties of acrylic foam tape absorb and dampen vibrations, maintaining bond strength over time.

Multi-directional Strength: Provides excellent resistance to shear, peel, and tensile loads in various directions. Flexibility: Accommodates thermal expansion and contraction of materials without compromising bond strength. Corrosion Prevention: Creates a barrier against moisture ingress, protecting the bonded materials from corrosion.

Fatigue Resistance: Distributes stress evenly, reducing the risk of fatigue failure common in point-fastened joints. Material Versatility: Effectively bonds dissimilar materials without the limitations faced by mechanical fasteners.

Vibration Damping

In precision equipment, vibration damping through adhesives can improve accuracy and reduce the need for additional isolation systems.

Many adhesives can absorb and dampen vibrations, enhancing the longevity and performance of the assembly.

This damping effect can improve user comfort in applications like automotive interiors and reduce noise in electronic devices.

Vibration damping properties of adhesives can extend the lifespan of sensitive components by reducing stress and fatigue.

In precision equipment, vibration damping through adhesives can improve accuracy and reduce the need for additional isolation systems. more..

Uniform Stress Distribution

In composite materials, adhesives can maintain the integrity of fibers and prevent delamination more effectively than mechanical fasteners.

Adhesives distribute stress evenly across the bonded surface, reducing the risk of localized failures.

This even distribution allows for better load bearing and can often result in a stronger overall bond than point-fastening methods.

The uniform stress distribution can lead to improved fatigue resistance, particularly in applications subject to cyclic loading.

In composite materials, adhesives can maintain the integrity of fibers and prevent delamination more effectively than mechanical fasteners.

Weight Reduction

Lighter assemblies can also contribute to improved handling and reduced wear in moving parts of machinery or vehicles.

Adhesives add minimal weight to the assembly, crucial in industries like automotive and aerospace.

The weight savings can translate directly into improved fuel efficiency, increased payload capacity, or enhanced performance.

In marine applications, even small weight reductions can lead to significant fuel savings over the lifetime of an aircraft. more..

Temperature-Related Benefits of Adhesives

- Thermal Insulation: Many adhesives act as insulators, protecting the bonded materials.

- Stress Distribution: Even distribution of thermal stresses across the bond line.

- Coefficient of Thermal Expansion (CTE) Management: Some adhesives can bridge CTE mismatches between different materials.

- Chemical Resistance: High-temperature adhesives often offer excellent chemical resistance as well.

Temperature Performance Across Industries

- Standard Steel Bolts: -20°C to 150°C

- High-Temp Alloy Fasteners: -40°C to 250°C

- Epoxy Adhesives: -40°C to 180°C

- Silicone Adhesives: -65°C to 300°C] more..

Superior Corrosion Resistance in Joining Applications

Long-Term Cost-Effectiveness: Reduced maintenance needs and extended longevity of adhesive bonds provide superior long-term corrosion protection.

Inherent Corrosion Resistance: Many adhesives are chemically inert, preventing reaction with corrosive elements and eliminating galvanic corrosion risks.

Protective Barrier Formation: Adhesives create a continuous, sealed bond that shields joined materials from moisture and corrosive agents.

Material Integrity Preservation: Unlike fasteners, adhesives don’t require holes in materials, maintaining protective coatings and natural corrosion resistance.

Specialized Formulations: Corrosion-inhibiting additives and environment-specific adhesives offer tailored protection for harsh conditions. more..

Superior Sealing Properties

The seamless nature of adhesive bonds can improve aerodynamics in transportation applications, potentially enhancing fuel efficiency.

Adhesives create a continuous bond, effectively sealing against moisture, dust, and other contaminants.

This sealing ability can enhance product durability, prevent corrosion, and maintain the integrity of sensitive components.

In electronics or automotive applications, adhesive seals can provide excellent protection against environmental factors like humidity and pollutants.

The seamless nature of adhesive bonds can improve aerodynamics in transportation applications, potentially enhancing fuel efficiency.

Enhanced Durability

In harsh environments, such as marine or chemical processing applications, specialized adhesives can outperform mechanical fasteners in longevity and reliability.

High-performance adhesives can provide bonds that are as strong or stronger than traditional fasteners, with improved resistance to environmental factors.

Many modern adhesives offer excellent resistance to chemicals, UV light, and extreme temperatures, often outlasting the materials they’re bonding.

The flexible nature of many adhesives allows them to absorb shock and movement, potentially increasing the overall lifespan of the assembly.

Multi-Material Bonding

The ability to bond dissimilar materials allows for optimal material selection for each component, potentially improving overall product performance.

Modern adhesives can effectively join dissimilar materials that would be challenging to fasten mechanically.

This capability opens up new possibilities in product design and material selection, driving innovation across industries.

In electronics, adhesives can bond metals to plastics or ceramics, enabling more compact and versatile designs.

Improved Aesthetics

In industries like furniture or interior design, adhesive bonds allow for sleek, modern aesthetics that align with contemporary design trends.

Adhesives create invisible joints, resulting in a cleaner, more professional appearance.

This seamless look is particularly valuable in consumer products, architectural applications, and high-end goods.

The absence of visible fasteners can enhance the perceived quality and value of products, potentially commanding higher market prices.

In industries like furniture or interior design, adhesive bonds allow for sleek, modern aesthetics that align with contemporary design trends. more…

Why choose Austen Tapes?

Cutting-edge adhesive technologies

✓ 3M VHB Tapes for permanent, invisible bonds

✓ tesa® ACXplus for high-performance applications

✓ Eco-friendly packaging tapes for sustainable operations

✓ Continuous innovation to meet evolving industry needs

Expert guidance

✓ One of fewer than 10 UK companies with our level of specialist supplier approvals

✓ Decades of experience in industrial adhesive solutions and vehicle body building

✓ Commitment to long-term partnerships with our clients

✓ Continuous innovation to meet evolving industry needs

Dedicated Professionals Ready to Assist You

Neil Howie

Managing Director

Manages finances, IT, safety, and quality controls

Joe Dimarino

Operations Director

Oversees internal operations and customer service

Mark Knee

Sales Director

Leads technical team and product testing

Call To Discuss Your Requirements

01892 832141

Consulting & Process Audit

Replace Traditional Fasteners with Advanced Adhesive Solutions

Austen Instant Tapes is committed to partnering with the world leaders in adhesive tape manufacturing, maintaining the most qualified project development engineers, and offering the broadest converting capabilities in the industry.

Reduction in Assembly Time

Lower Production Costs

Product Lifespan

As authorized distributors for tesa and 3M Industrial Products, we provide expert guidance on implementing advanced adhesive solutions.

Schedule a free consultation with our technical team to discover how we can help optimize your manufacturing process.

Ready to Modernize Your Assembly Process?

Schedule a free consultation with our technical team to discover how we can help optimize your manufacturing process.

Work with our team to identify the optimum adhesive, design, and process for each of your applications to ensure that your final process is running Lean to increase potential profit.

Designed to help you save time and money, our process audits add value to your product by providing a more diverse selection of adhesive materials to assist your company in meeting your goals.

Our application engineers consult with your team of professionals remotely or on-site to determine your needs, drawing from years of experience in the industry to solve application problems and inefficiencies.

Elevate Your Manufacturing with Austen Instant Tapes

Take your production to the next level with our cutting-edge adhesive solutions.

📞 Call 01892 832141

✉️ Email: Contact Form

Discover innovative adhesive solutions for specialist environments and applications.

Blog

Automotive Industry Closing Holes in the Vehicle Body

Discover how innovative adhesive solutions are revolutionizing the way the automotive industry seals vehicle body holes, but at what cost?

tesa® Bonding Solutions for Trucks and Trailers

Optimise your truck and trailer’s performance with tesa®’s high-performance sealing and bonding solutions.

Special Adhesive Tapes for Electric Vehicles

Fueling the future of electric vehicles, specialized adhesive tapes enhance safety and performance—discover how these innovations are transforming mobility.

Tape Converting for Industrial Applications

Achieve optimal efficiency in industrial applications with advanced tape solutions; discover how they can transform your workflow and protect your surfaces.

Adhesives Streamlining Production: The Future of Vehicle Body Assembly

Just when you thought vehicle assembly couldn’t get any more efficient, innovative adhesives are revolutionizing the process in unexpected ways. Discover the future now.

Adhesives Vs Traditional Fasteners

Understand the key differences between adhesives and traditional fasteners to discover which option best suits your project needs. The choice could surprise you!